Have you ever wondered what makes a cooler truly outstanding? The answer lies in the innovative world of Rotomolded Technology. In this blog, we will take you on a journey through the fascinating realm of Rotomolded Coolers, exploring what they are, how they work, and why they have become the go-to choice for outdoor enthusiasts and adventurers alike.

What is Rotomolded Technology?

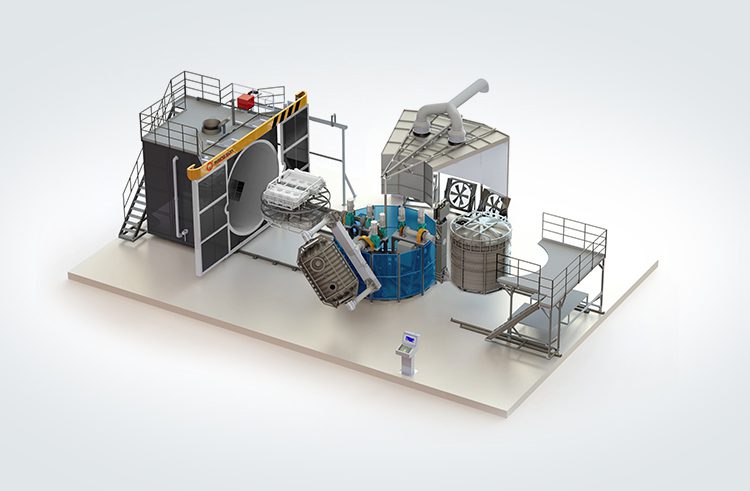

Rotomolded Technology, short for rotational molding, is a manufacturing process that has transformed the way coolers are made. It’s a method that fuses science, engineering, and craftsmanship to create rugged, durable, and high-performance coolers. But how does it work?

The Rotomolding Process

At its core, the rotomolding process is a beautiful dance of simplicity and precision. It all begins with a specially designed mold, typically made from aluminum. This mold is divided into two halves, and the magic begins.

Step 1: Material Loading

First, polyethylene pellets, the raw material of choice for rotomolded coolers, are loaded into the mold. This material is known for its remarkable durability, UV resistance, and insulating properties.

Step 2: Heating and Rotation

The mold is then heated and slowly rotated in all three dimensions simultaneously. The heat causes the polyethylene pellets to melt and evenly coat the interior of the mold. This rotation ensures uniform thickness, creating a single, seamless piece.

Step 3: Cooling and Solidifying

As the mold continues to rotate, it gradually cools, solidifying the now-formed cooler shell. This slow cooling process prevents warping or distortion, ensuring a flawless end product.

Step 4: Unveiling the Cooler

Once the cooling is complete, the mold is opened, revealing a seamless, one-piece cooler. This structure not only enhances the cooler’s durability but also minimizes potential weak points where leaks could occur.

The Evolution of Rotomolded Coolers

Rotomolded coolers have come a long way since their inception. Originally designed for industrial applications like storage tanks and playground equipment, they have found their way into the hearts of outdoor enthusiasts, campers, fishermen, and anyone who appreciates a cooler that can take a beating.

Durability Beyond Compare

One of the standout features of rotomolded coolers is their unmatched durability. With no seams, joints, or weak points, these coolers can withstand extreme conditions, from rough handling to being tossed around on a fishing boat. They’re built to endure the toughest adventures and still keep your drinks ice-cold.

Ice Retention Superstars

Rotomolded coolers are the kings of ice retention. The thick walls and insulation properties of the polyethylene construction trap cold air inside, keeping your ice frozen for days on end. This means you can enjoy refreshing beverages and keep your catch of the day fresh, even on extended trips.

Rugged and Bear-Proof

Yes, you read that right—some rotomolded coolers are bear-proof. Their robust construction and heavy-duty latches make them virtually impervious to the curious claws of these powerful creatures. So, whether you’re in bear country or not, you know your cooler’s contents are safe.

A comprehensive Guide on How to Choose the perfect Ice Chest Cooler for your outdoor adventure

Rotomolded Coolers vs. Traditional Coolers

Now that we’ve uncovered the wonders of rotomolded technology in coolers, let’s delve into the key advantages that set them apart from their traditional counterparts.

Thermal Insulation

Traditional Cooler: Thin walls and poor insulation often lead to rapid ice melting. Your perishables might not stay safe for long, especially in hot weather.

Rotomolded Cooler: Thick, rotomolded walls with superior insulation capabilities ensure ice retention for days. Your beverages and food will stay fresh and cold.

Durability

Traditional Cooler: Made with multiple parts and seams, traditional coolers are prone to wear and tear. They may not withstand rough handling or heavy loads.

Rotomolded Cooler: A single, seamless structure makes rotomolded coolers incredibly durable. They can handle rough treatment and last for years.

Bear-Proofing

Traditional Cooler: Traditional coolers offer no protection against curious wildlife, posing a risk to both your supplies and the animals.

Rotomolded Cooler: Some rotomolded coolers are certified bear-proof, providing peace of mind in bear country and ensuring your cooler remains intact.

Weight and Portability

Traditional Cooler: Traditional coolers can be heavy and cumbersome, especially when loaded with ice and supplies.

Rotomolded Cooler: While still robust, rotomolded coolers are designed with portability in mind. They often feature comfortable handles and ergonomic designs for easier transport.

Longevity

Traditional Cooler: Traditional coolers may require frequent replacement due to wear and tear, costing you more in the long run.

Rotomolded Cooler: With their superior build quality, rotomolded coolers are an investment that pays off over time, providing long-lasting performance.

Conclusion

Rotomolded technology has revolutionized the world of coolers, providing outdoor enthusiasts and adventurers with a cooler that’s as tough as they are. These coolers, with their exceptional durability, ice retention, and bear-proof capabilities, have become a game-changer for those who demand the best in their outdoor gear.

So, the next time you plan an adventure or a weekend getaway, consider investing in a rotomolded cooler. It might just be the perfect companion for your journey, keeping your beverages cold, your catch fresh, and your worries at bay. With rotomolded coolers, the only thing you’ll need to focus on is making unforgettable memories in the great outdoors.